Concentrated Solar Power (CSP) or Concentrated Solar Thermal (CST) supplies green electricity, green heat and green hydrogen. The technology is mature and has a global track record of more than three decades. More than 6.6 gigawatts of capacity from CSP power plants have been installed worldwide.

Concentrated Solar Power (CSP)

CSP – A multi-talent

The primary product of CSP plants is heat, obtained by concentrating sunlight. This heat can be used in many different ways.

The most common application is electricity, which is generated in a Concentrated Solar Power plant. A CSP plant works like a traditional steam power plant: it produces steam to run a turbine that generates electricity via a generator.

How concentrating solar thermal works

Concentrating solar thermal energy uses the light of the sun as a raw material. The rays of light are bundled with the help of mirrors that are aligned with the path of the sun and directed to a specific point or to a focal line. This effectively concentrates the light energy. This concentration generates heat, as in a burning glass. Hence the name: Concentrated Solar Power.

There are various CSP techniques. What they all have in common is that they convert sunlight into high temperatures.

Functionality of a solar thermal power plant, shown here for a solar tower power plant

German Aerospace Center DLR 2021

Techniken zur Konzentration der Solarstrahlung

In practice, three different techniques are used to concentrate solar radiation:

Three different techniques for concentrating solar radiation: solar towers, parabolic troughs, linear Fresnel systems.

DCSP

- Solar Towers

In solar tower power plants, mirror surfaces that follow the path of the sun on two axes direct the sunlight onto a central radiation receiver (receiver) mounted high on a tower. A medium absorbs the heat there. Liquid salt is usually used as the medium. Other media with less commercial importance so far are air, water and thermal oils. The medium transports the energy of the solar radiation into the heat storage tank and on to the power plant circuit. The mirror surfaces, also called heliostats, are up to 200 square metres in size. In commercial power plants, several thousand of them are aligned in a semicircle or circle with the solar tower. Their strong radiation concentration generates surface temperatures at the receiver that heat the heat transfer medium to around 600 °C.

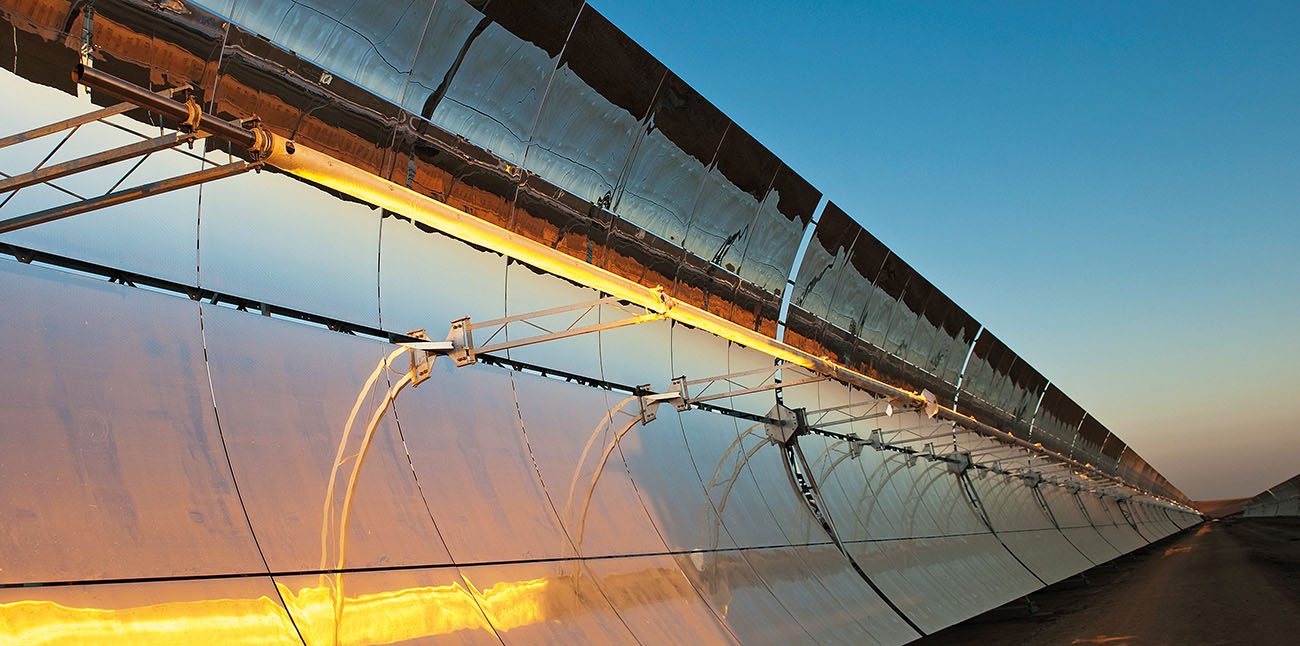

- Parabolic troughs

Parabolic trough power plants have been the most frequently realised commercially to date. Parabolically shaped troughs, also known as collectors, are moved along an axis with the help of hydraulic drives to follow the path of the sun. They focus the light rays at the focal point of the trough onto an absorber tube that runs lengthwise through the trough at a distance of half the radius of the mirror. The energy of all incident light rays is combined in this focal line, effectively concentrating the light energy. In this absorber tube, a special thermal oil or a fluid made of other material absorbs the heat. A pump system directs the highly heated fluids into the heat exchanger, which is connected to a water-steam circuit.

The absorber tubes are the heart of the collectors: an optically selective coating on the tube absorbs the visible light and simultaneously inhibits the radiation of heat. The absorber tube is surrounded by a slightly larger glass tube and, similar to a thermos flask, there is a vacuum between the two tubes. This significantly reduces heat loss through radiation.

The collectors are up to seven metres wide and up to 200 metres long. The thermal oils commercially used today in the receivers allow an operating temperature of up to 430 °C. New media are currently being researched. New media are currently being researched and tested that can absorb higher temperatures without damage, e.g. liquid salts with operating temperatures of up to 600 °C.

- Linear Fresnel Systems

Linear Fresnel Collectors function in a similar way to parabolic rotors. However, the concentrating mirror is divided into elongated, individual facets that are also aligned with the position of the sun. They are arranged horizontally at some distance above the ground. The absorber tube is mounted above the mirrors. The frames that hold them are installed in a fixed position. This type of construction is very robust and can therefore withstand high wind loads; in addition, small designs are possible, which also allows installation on flat roofs. The special collector geometry results in a lower optical efficiency, but this is compensated for by lower collector costs.

The thermal storage

An important component of solar thermal power plants is the integrated thermal storage. CSP is able to first convert energy from solar radiation into thermal energy. Depending on the heat transfer medium used (Heat Transfer Fluid HTF), this heat can either be stored or used directly to generate heat or electricity. The thermal energy storage thus enables the use of solar radiation 24 hours a day. CSP also lets the sun shine at night, so to speak. The warmth of the sun makes it possible.

Functionality of an integrated CSP-PV hybrid power plant

TSK Flagsol Engineering GmbH

Hybrid power plants

Hybrid power plants, in which solar thermal power plants are coupled with PV or other technologies, are becoming increasingly important: During the hours of sunshine, PV power plants supply cheap solar power. At the same time, CSP power plants feed the heat into thermal storage. After sunset, this is then ready for power generation. By combining the two solar technologies, controllable and inexpensive green electricity can be generated.

Green heat with CSP

With its technological possibilities, concentrating solar thermal energy can contribute to the success of the German and European heat transition.

Concentrating collector systems produce controllable heat between 50 and about 430 °C operating temperature. In this range, the systems can provide green process heat as well as local and district heating even in Germany. Thanks to the integration of heat storage, a high degree of solar coverage of up to 65 – 75% can be achieved. The hybridization of a solar thermal system enables the year-round provision of renewable heat.

Green hydrogen – a beacon of hope

In order to make hydrogen an important factor in the energy and heat transition, renewable electricity must be available at the lowest possible cost for its production. The conversion efficiencies must be as high as possible and the plants for power generation and electrolysis must be utilized around the clock if possible. Here, the CSP can make a decisive contribution with its ability to supply cheap energy 24/7.

The Contribution of CSP to Hydrogen Production

Representation modified from Herbert Smith Freehills